Design & Engineering

Design & Engineering Processes

The Camaco engineering and design team provides the best-in-class service to our customers; continuously reviewing and improving our engineering disciplines and design processes, including stamping, fine-blanking and welding manufacturing processes; as well as, CAD standards and Global/Offshore Design (LCC) processes that allow us to provide 24-hour design services.

Computer Aided Design (CAD)

Camaco is the global leader in automotive seat structure engineering and design. Expertly utilizing Catia and NX CAD software; as well as 3Dexperience (3DX) and Teamcenter PLM to seamlessly integrate with our customers’ needs to provide best-in-class service and support.

Critical Design Review (CDR)

At Camaco, we pride ourselves on adhering to accepted engineering principles and disciplines. In depth critical design review gateway process is in place to ensure that thorough virtual engineering and preventive analyses are completed to meet and exceed product specifications prior to design release.

Design Guidelines

At Camaco, design guidelines, drafting templates and Knowledge-Based Engineering (KBE) tools drive our process efficiency

DFMEA

Failure mode analyses starts at early concept phase and update contiguously during the development

CC and SC

All critical features and aspect of component/sub-assemblies are communicated by assigning CC and SC on the drawings

GD&T

ASME 14.5 & ISO standards of Geometric Dimensioning and Tolerancing are used

Computer Aided Engineering (CAE)

At Camaco, we leverage advanced CAE methods across all phases of product development to meticulously validate structural performance through comprehensive analysis. Our arsenal of cutting-edge CAE technologies encompasses static and dynamic FEA, rigid body kinematics, fatigue assessment, NVH analysis, and tolerance analysis.

Finite Element Analyses (FEA)

Through static and dynamic FEA simulations, we prioritize occupant safety, optimal design, and seamless functionality of our seat structures and mechanisms. Our ability to swiftly implement design team requests facilitates lightning-fast development cycles, fostering the creation of groundbreaking/innovative seat structures, recliners, tracks, latches.

Dynamic Simulation – ADAMS

A multibody dynamic simulation software is used widely to understand the relative motion of parts and how forces are transferred in the mechanism including the inertia effect and stroke / effort prediction.

3DCS

3DCS a 3dimensional tolerance analysis tool is used to perform the system level 3-dimentional tolerance stack analysis

Abaqus

Abaqus static simulations is to analyze stresses of components at a finer scale, providing detailed insight into structural behavior

Enventive

Enventive is used to run the 2D tolerance and force analysis on the complex product

Creo

Creo is used for quick design, simulate and analyze the mechanisms for effort and travel studies.

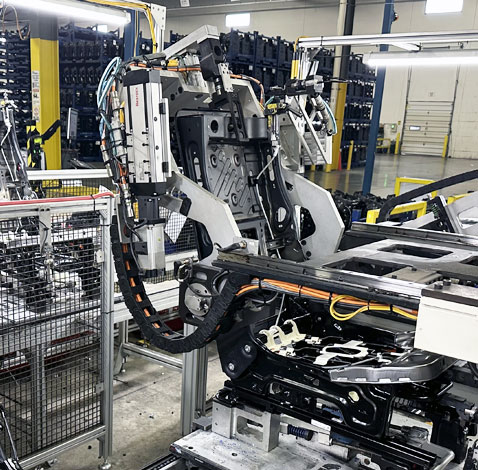

Manufacturing

Camaco has a wide array of Manufacturing Capabilities that are built on Innovation, Technical Expertise, Customization, and intense focus on Quality Control.

Vertical Integration

Camaco uses vertical integration in our manufacturing process and capabilities to control quality, cost, and C02 emissions.

Best in Class Seat Designs and State of the Art Global Manufacturing

Through quality metrics, cost management systems, advanced engineering solutions and state of the art manufacturing processes, we continually strive to achieve customer satisfaction through flawless execution.