Program Execution

Camaco Engineering is fully equipped, in personnel, process, & CAE to execute the most complex structures programs around the globe.

Core product development allows Camaco to employ vertically integrated mechanisms into future programs, enhancing the quality of system integration.

Engineering resources are deployed on all build-to-print programs to ensure all manufacturing feasibility issues are addressed in the design.

The Critical Design and Manufacturing review process as well as the Fixture Concurrence process is used for all programs regardless of design responsibility.

Camaco executes many programs in this manner. A few of our customers have internal seat structure design teams that will maintain overall system integration responsibility with Camaco being responsible for detailed design of various sub-systems.

These types of programs run very similar to the Design Responsible programs

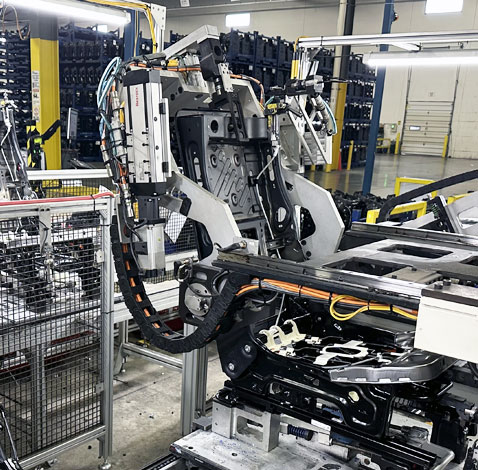

Manufacturing

Camaco has a wide array of Manufacturing Capabilities that are built on Innovation, Technical Expertise, Customization, and intense focus on Quality Control.

Design & Engineering

The Camaco engineering and design team provides the best-in-class service to our customers.

Best in Class Seat Designs and State of the Art Global Manufacturing

Through quality metrics, cost management systems, advanced engineering solutions and state of the art manufacturing processes, we continually strive to achieve customer satisfaction through flawless execution.