Manufacturing

Camaco provides its customers a number of innovative solutions by utilizing state of the art processes and technology to stay at the forefront of high-quality manufacturing. The company’s lean manufacturing techniques comprise flexible manufacturing cells, automated assembly lines and robotic welding to deliver world-class products.

Complex Seating Structures

Camaco is at the fore front of Designing and Producing complex seating structures and mechanisms for Customers all over the world.

Manufacturing Capabilities

Camaco has a wide array of Manufacturing Capabilities that are built on Innovation, Technical Expertise, Customization, and intense focus on Quality Control.

Stamping

Camaco utilizes both low and high tonnage presses to produce precise metal stampings and components designed specifically for Seating systems all over the world.

Welding

Camaco specializes in numerous Welding processes including Laser, MIG, TIG, and Resistance Welding to name a few. We automate and innovate our Welding systems to produce high quality and precise seating components.

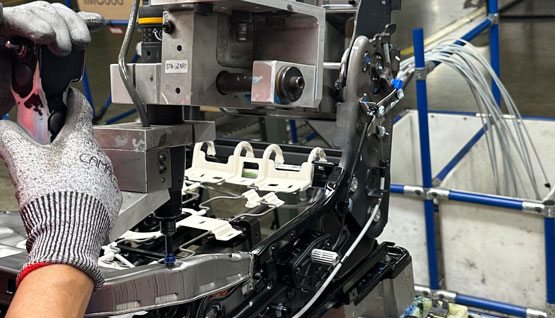

Assembly

Our various Assembly processes are highly coordinated and focused on Quality, Efficiency and end product lifetime performance. We use advanced product testing systems and vision systems to help ensure that all our conveyors, assembly fixtures and processes are designed to produce world class quality components.

Design & Engineering

The Camaco engineering and design team provides the best-in-class service to our customers.

Vertical Integration

Camaco uses vertical integration in our manufacturing process and capabilities to control quality, cost, and C02 emissions.

Best in Class Seat Designs and State of the Art Global Manufacturing

Through quality metrics, cost management systems, advanced engineering solutions and state of the art manufacturing processes, we continually strive to achieve customer satisfaction through flawless execution.